Traditional battery testing systems require weeks of on-site integration, compatibility troubleshooting, and control programming. FUSION changes that. Every system is pre-integrated, validated, and ready for immediate deployment.

Single Purchase Order: One complete system. One delivery. One point of contact for support.

Pre-Integrated Controls: Controls communicate automatically—no programming, no interfaces, and no compatibility issues.

Immediate Deployment: Systems arrive assembled, tested, and validated. Start testing in days, not weeks.

Proven Reliability: Built on platforms with hundreds of thousands of channels in active service worldwide.

Every FUSION configuration delivers the same promise: integrated testing without the integration headaches.

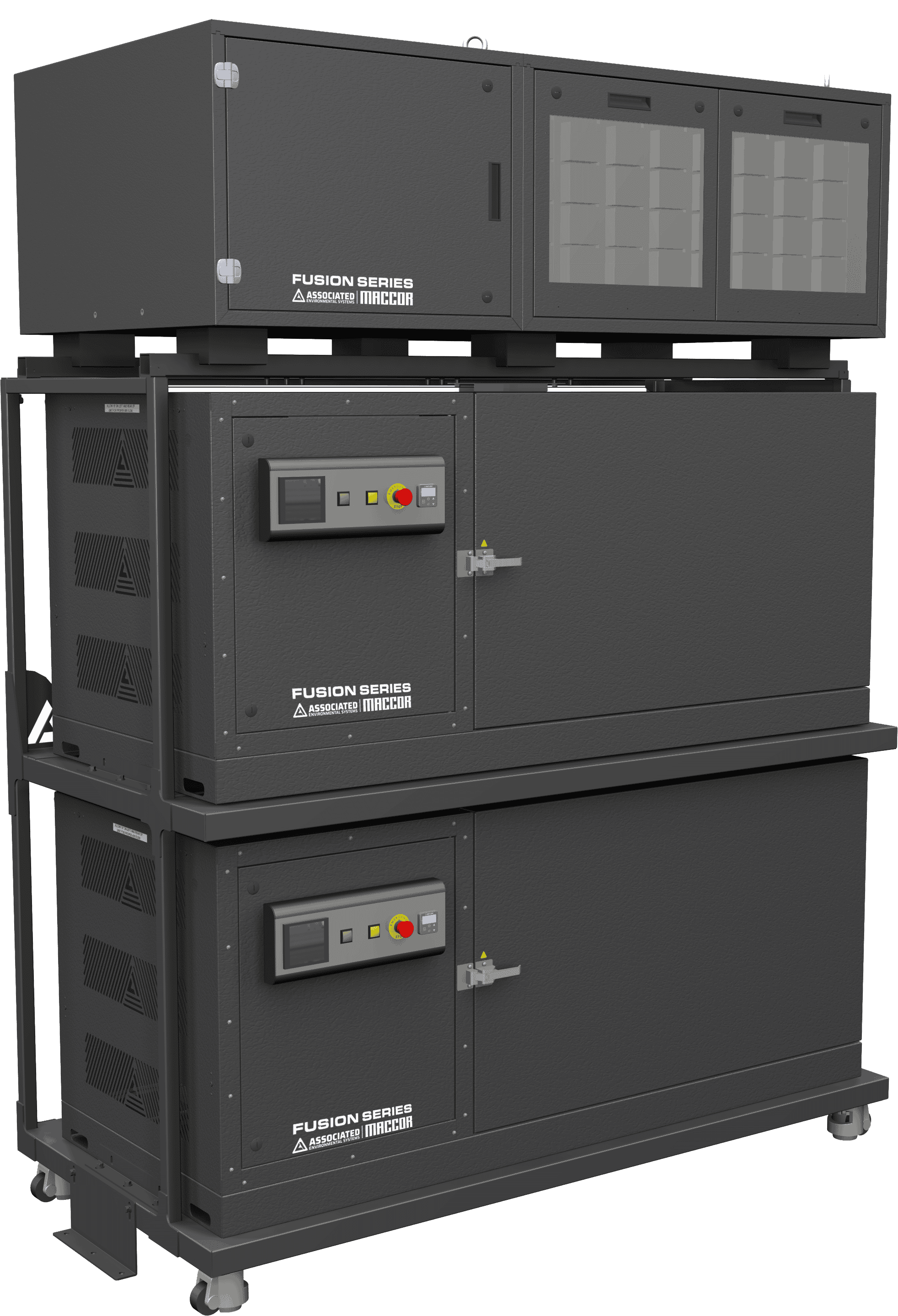

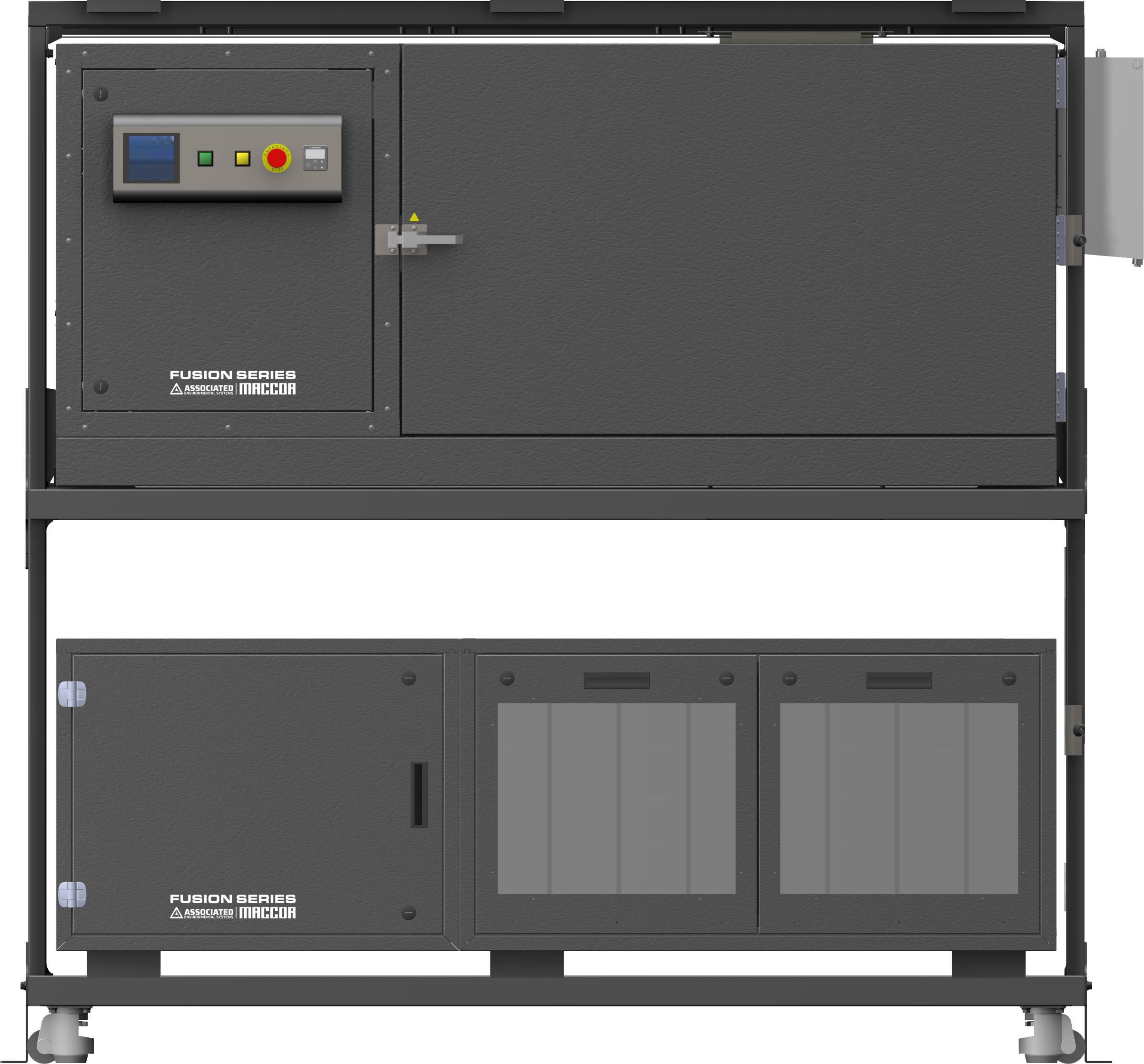

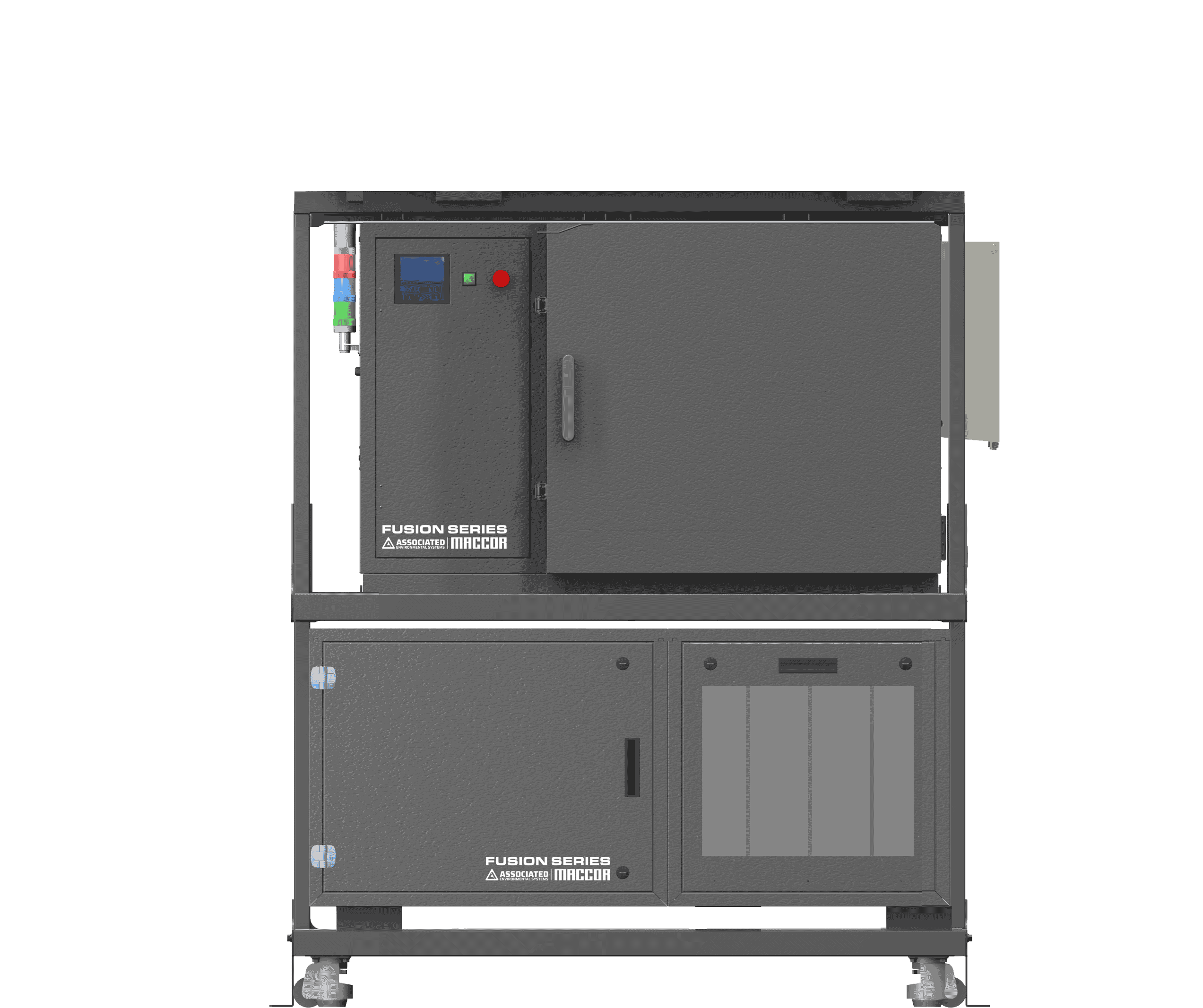

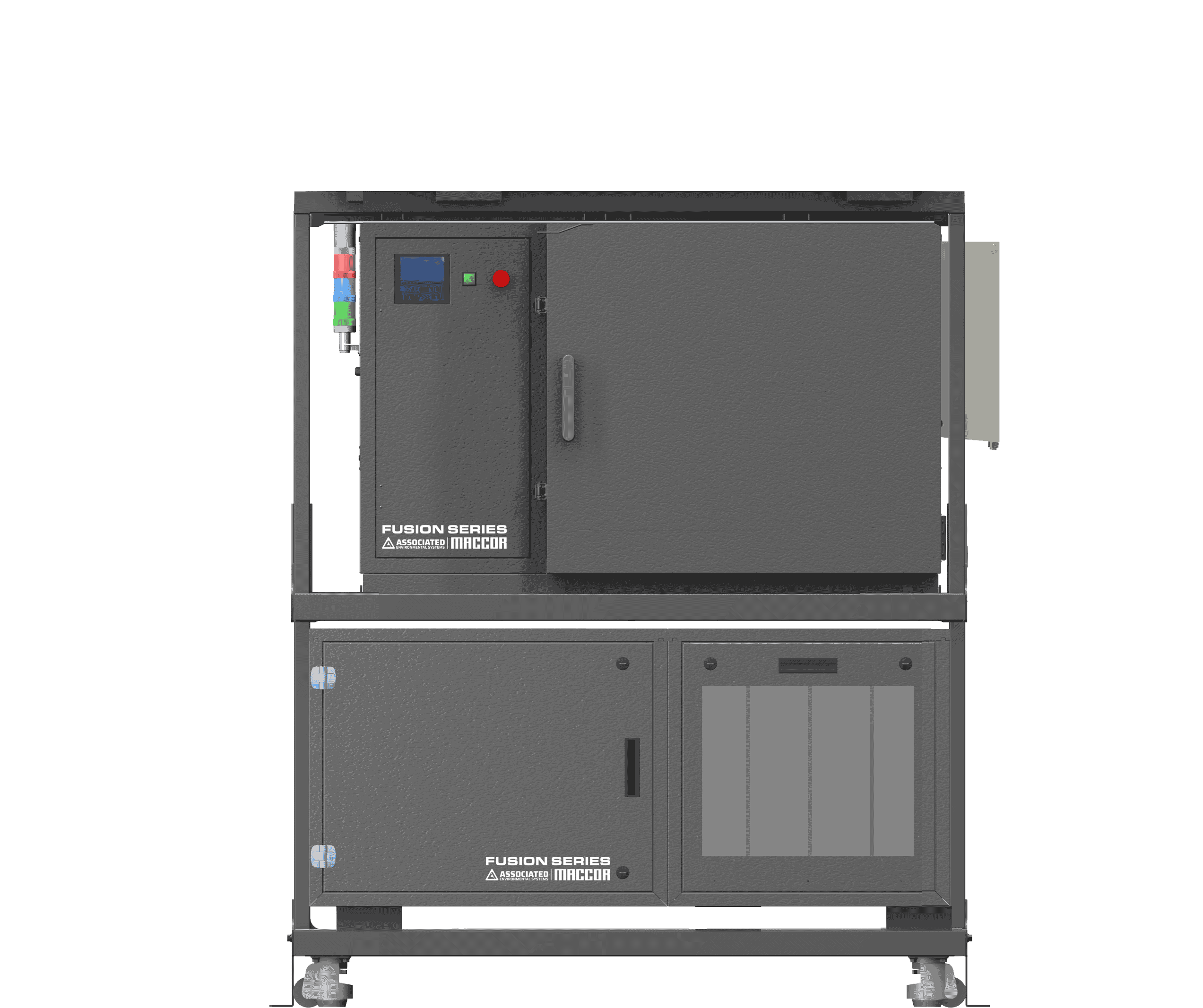

FUSION systems scale from small-cell research to full module and pack validation, matching your current requirements while adapting to tomorrow’s needs:

Whether you need maximum throughput for cell development or maximum power for EV validation, there's a FUSION system built for your testing goals.

High-capacity dual-chamber system for maximum throughput.

Single-chamber design optimized for high-power testing.

Ultra-dense channel system for high-volume cell testing.

Flexible mid-range system with versatile current control..

For over a decade, AES and MACCOR have delivered integrated battery testing solutions as one team. Now that partnership is built into every FUSION system, bringing customers the reliability of two proven U.S. manufacturers in a single, unified product.

Years of joint installations mean every system ships fully integrated. Customers get unified controls, coordinated support, and the confidence of advanced battery test equipment co-engineered and supported by both manufacturers, from design to delivery.

All FUSION battery test solutions include:

What are the benefits of a completely integrated battery test system?

The benefits of a completely integrated battery test system include faster setup, simplified support, and fewer compatibility issues between components. FUSION delivers these advantages by uniting the cycler, chamber, safety systems, and controls in one product, so testing can start immediately without the delays of multi-vendor integration.

What is regenerative battery testing?

Regenerative battery testing is when discharge energy is returned to the grid instead of wasted as heat. FUSION systems feature up to 90% return-to-grid efficiency, lowering energy costs and making high-power validation more sustainable.

What should I look for in industrial battery testing equipment?

When choosing industrial battery testing equipment, look for accuracy, safety, scalability, and ease of use. FUSION combines all of these in a turnkey platform, offering a single software platform, coordinated support, and proven reliability from two U.S. manufacturers.

What should I look for in a battery equipment integrator?

When selecting an integrator, you should consider your timeline and your end goal. You want a partner that can support you when issues arise, both from a service and support perspective. The FUSION System is 100% made and supported in the USA, with multiple service teams fully trained and ready to provide assistance, along with backup parts for uninterrupted operations.